Teflon

- Jay Sardesai

- Feb 26, 2021

- 4 min read

Teflon, also known as PTFE(polytetrafluoroethylene), is a polymer with a variety of uses, such as being a non-stick coating, both for cookware and for walls to prevent insects from climbing up. PTFE is also used as an igniter for rockets, and to coat the surfaces of solar panels. It is also used as a lubricant for bicycle chains and moving machine parts, and as a gasket (a seal between two parts to prevent leakage) due to its high heat resistance. PTFE now accounts for 60-65% of the total market for fluoropolymers worldwide, and production of it increases by 7% per year. Teflon has the repeat unit shown below:

Teflon was inadvertently discovered by Roy J. Plunkett, a chemist working for DuPont, in 1938. Roy J. Plunkett was trying to find new CFC refrigerants, of which the dangers to the ozone layer had not yet been discovered. He had chlorinated tetrafluoroethylene gas, before storing it at low temperatures, creating Teflon. Even though it, a white powder, was not what Plunkett was looking for, he still ran tests on it, finding that its surface friction was very low, it was inert, and that it was relatively heat-resistant (Teflon has a melting point of 327°C). These properties would make it suitable for one of its most famous uses, as a non-stick coating for pans and other cookware. In 1951, Roy J. Plunkett was given the John Scott Medal for his discovery.

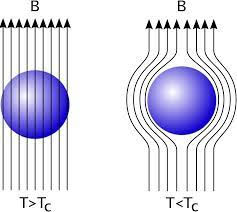

Teflon has a very low coefficient of friction (0.04) due to the very low intermolecular forces between PFTE chains, allowing them to slide past each other easily. Furthermore, due to the high reactivity of the fluorine atoms, the carbon-fluorine bonds are very strong and unreactive, making PFTE almost entirely inert, as well as fireproof. As Teflon is non-polar, it is also hydrophobic, further helping it in its application as a non-stick coating for cookware.

While a link between Teflon and cancer has been claimed many times, as of today, there is no evidence that Teflon causes cancer. One of the main issues that the controversy has developed around is the use of Perfluorooctanoic Acid (PFOA) to make Teflon. There is mixed evidence as to whether PFOA causes cancer, but importantly it is not present in the finished product in potentially harmful amounts, and not much greater than the background level of PFOA in humans, as due to its inert nature, PFOA has entered the food chain.

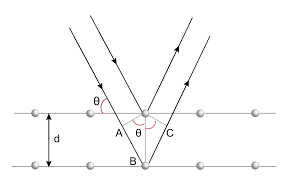

The most common method of manufacture for PTFE is the polymerisation of tetrafluoroethylene(TFE), normally using disuccinic acid peroxide or ammonium persulfate as an initiator, where the initiator binds itself to a TFE molecule by addition, breaking the carbon-carbon double bond, and allowing the TFE molecule to bind to another TFE molecule, breaking their double bond, and continuing until all TFE molecules in the vicinity have been used up. TFE itself is synthesised from fluorspar (calcium fluoride), chloroform (trichloromethane), and hydrofluoric acid at high heat. TFE is very flammable and can be explosive, and as such is stored at low temperature and pressure away from oxygen.

Although cancer is not a concern when using Teflon, a more serious risk is the thermal decomposition of Teflon at high temperatures. Teflon begins to undergo decomposition at 200°C, releasing several fluorocarbon gases, which can cause polymer fume fever, leading to headaches, chills, and a fever. However, significant quantities are only emitted when the temperature passes 260°C, and polymer fume fever is usually only observed at temperatures in excess of 300°C. While polymer fume fever is not fatal, the gases have a much more severe effect on birds and can cause death.

In addition, some solar panels are now coated with Teflon. This is to prevent dust and dirt from sticking to them, which would block light from reaching the solar panels, reducing their power output. Moreover, Teflon is hydrophobic, both protecting the solar panels from water and allowing water to run off them easily. Teflon is also lighter and less fragile than glass, very flexible, durable, and allows >95% of light through, leading to it replacing glass in many cases.

PTFE is also a common fuel for electric spacecraft plasma propulsion. This is where an electric current is passed through the fuel, sublimating it, and leading to the conversion of the solid PTFE into a plasma. The sublimation forces the plasma out between two charged plates, finishing the circuit between them, and allowing a current to flow through. The electromagnetic field due to the current then exerts a Lorentz force on the plasma, forcing it out of the thruster at high speeds, and propelling the spacecraft forward. The plates are then recharged before more of the PTFE is sublimated for another pulse. While the force exerted by these thrusters is low, due to the effective lack of friction in space, over time these thrusters can be used to accelerate to very high speeds.

The most common use of PTFE, however, is as an electrical insulator, due to its very poor ability to conduct electricity, and high melting point. While PTFE has a higher cost than polythene, due to its superior durability and heat resistance, it has become a widespread choice for cable insulation. Overall, despite the vast array of uses for PTFE, over 50% of the material is now used as an insulator for cables, circuit boards, and other electronics

Sources:

Comments